Bright Steel And Aluminium Works

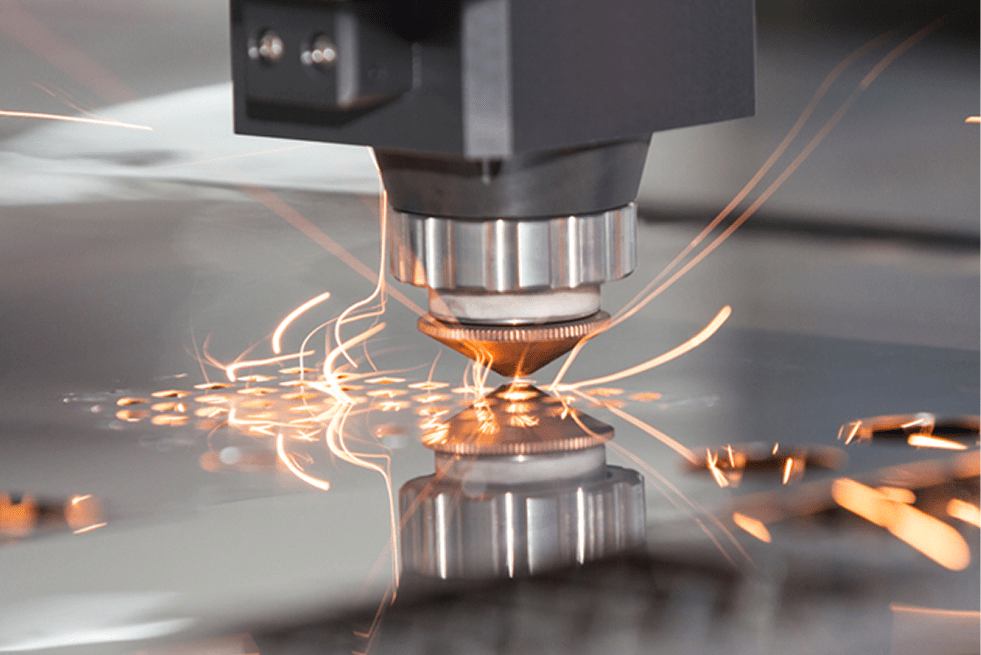

Metal laser cutting has evolved significantly over the years, offering efficient solutions for fabricating a wide range of metal components. As technology continues to advance, the future of metal laser cutting holds even more exciting possibilities. In this blog post, we will explore the upcoming trends and innovations in metal laser cutting technology, shedding light on the transformative changes that are set to shape the industry.

Ultrafast Laser Cutting: Ultrafast laser cutting is poised to revolutionize the industry by achieving remarkable cutting speeds while maintaining exceptional precision. By utilizing ultrafast laser pulses, this technology enables rapid material removal and reduces heat-affected zones, resulting in cleaner cuts and reduced processing times. This advancement holds great potential for industries that demand high throughput and intricate designs.

Intelligent Machine Learning and AI Integration: The integration of machine learning and artificial intelligence (AI) into metal laser cutting systems will enhance automation, efficiency, and quality control. By leveraging advanced algorithms, these systems can analyze vast amounts of data in real time, optimizing cutting parameters, predicting tool wear, and detecting anomalies. This integration will enable self-learning machines that continuously improve performance and adapt to changing conditions.

Additive Manufacturing and Laser Cutting Synergy: The combination of additive manufacturing (3D printing) and metal laser cutting technology offers new possibilities for complex and customized part production. Laser cutting can be utilized to add fine details, surface finishes, or intricate features to additively manufactured components. This synergy opens up opportunities for hybrid manufacturing processes, enabling the production of highly customized, functional, and lightweight structures.

Increased Integration with Robotics and Automation: Automation plays a vital role in improving productivity and reducing human error in manufacturing processes. Metal laser cutting technology will increasingly integrate with robotics, allowing for seamless material handling, part loading and unloading, and in-process inspections. Collaborative robots, equipped with advanced sensors and intelligent programming, will work alongside human operators, optimizing efficiency and safety.

Enhanced Material Versatility and Thickness Range: Future advancements in metal laser cutting will expand the range of materials and thicknesses that can be effectively processed. Laser cutting systems will be engineered to handle a broader spectrum of metals, including exotic alloys and high-strength materials. Moreover, improved beam delivery systems and cutting strategies will enable precise cutting of thicker materials, further expanding the application possibilities.

Green Laser Cutting: Sustainable and Eco-Friendly Solutions: Environmental sustainability is a growing concern in manufacturing. Future trends in metal laser cutting will focus on reducing energy consumption, optimizing material utilization, and minimizing waste generation. Green laser cutting technologies, such as beam shaping and pulse control, will contribute to the development of more eco-friendly and sustainable cutting processes.

The future of metal laser cutting technology holds immense promise, driven by advancements in ultrafast cutting, intelligent machine learning, additive manufacturing synergy, increased automation, expanded material versatility, and sustainable practices. These trends will shape the industry, enabling manufacturers to achieve greater efficiency, precision, and customization. As innovation continues to push boundaries, metal laser cutting will remain a key pillar of modern manufacturing, empowering industries across the globe.